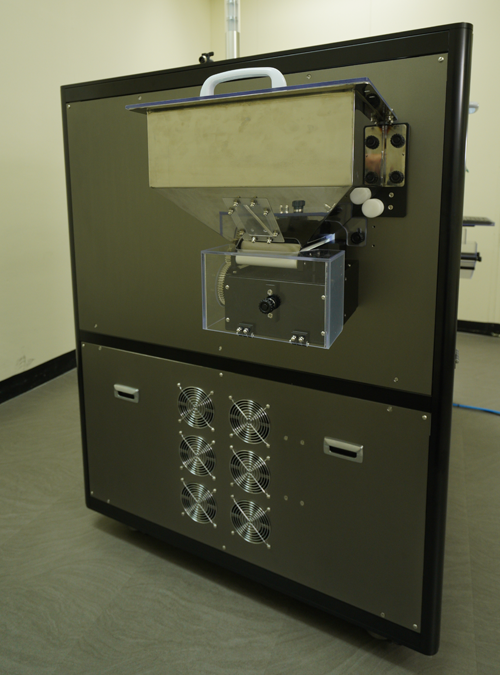

PRODUCT

AVIC22

VISUAL INSPECTION FOR SOFTGELS & HARD CAPSULES

Model AVIC22

- Size (W)x(D)x(H)

- 1,855mm x 1,064mm x 1,656mm

- Electricity

- 220V, 60Hz, single phase electric furnace

- Standard processing power

-

SoftgelHard capsule - 300,000 capsules/hour

#OVAL – 300,000 capsules/hour

#oblong – 250,000 capsules/hour - Machine weight

- 800KG

Characteristics

- Able to inspect Softgels and Hard Capsules by installing required change-parts.

- Easy to change from one product to another product

- Easy to clean

- Easy to operate

- Camera inspects entire surface of softgels while turning them 360°

- No defects are ejected into the bin for good softgels.

- Detectable range: 50 – 100 micron

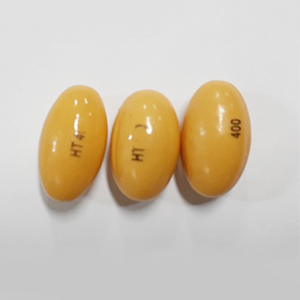

Softgels

Different types capsules

(transparent)

printing defects

capsules body color defects

One or two color classification

Different types capsules

(not transparent)

broken capsule

- As softgels pass through the inspection zone, cameras inspect softgels including both ends of the softgel while turning them 360° .

- Detect and reject foreign capsules and different color.

- Detect and reject stain on softgels and air bubbles or foreign material inside clear softgels.

- Detects and rejects different size, defective print and deformed shape.

-

Inspection rate

#OVAL – 300,000 capsules/hour

#oblong – 250,000 capsules/hour

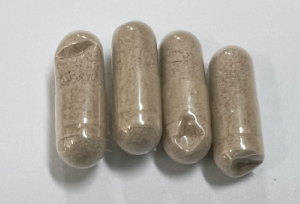

Hard Gelatin Capsules

hair inside the capsule

double fitted cap

distorted shape

black dot

- Able to inspect entire surface by a camera while turning 360°

- Detects and rejects stain, spot, different color, print, size, split capsules and deformed capsules.

- Inspection rate: 300,000 capsules/hour